|

Qingdao Perfect Roof Co.Ltd

|

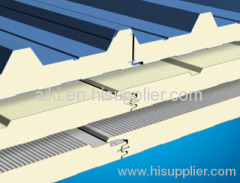

Metal Rock Wool (Mineral Wool) Sandwich Panel

| Price: | 1.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

It is for roofs and walls which require a high degree of resistance to fire. It is suitable for various roofs and walls referring to the large-sized

Metal Rock Wool Sandwich Panel(mineral wool panel) is made of two-layer weatherproof color plating steel plates or other metal plates and mineral wool sandwiched which is the best fireproof materials. he rock wool sandwich panel It is for roofs and walls which require a high degree of resistance to fire. It is suitable for various roofs and walls referring to the large-sized factory buildingsT, storages, exhibition halls, freezing stores, purification workshops, and more which features temp-keeping, heat insulation, weight-bearing, and weatherproof.

The metal rock wool sandwich panel achieves a notable reduction in air borne sound transfer, particularly when specifying a perforated liner. The impact of rain and hail on the metal sheet, a problem on most standard constructions, is greatly reduced when adopting the metal rock wool sandwich panel in thicknesses of 50-100mm with 100kg/m3 rock wool fibre insulation has achieved results of RW=29-30 dB according to UNI 8270/7 and 717/82.

Features and advantages of metal rock wool sandwich panel

1.Exemplary fire protection with rock wool steel sandwich elements

Fires at several locations in Europe have since many years confirmed the fire-resistant and fire-proofing effect of sandwich panels with rock wool core. Despite intensive flame application, the panels do not contribute to spreading or intensification of the fire, and only release small quantities of smoke. These characteristics are now also reflected in testing to European standards.

Sandwich panels that are classified in building materials class A2-s1d0 throughout Europe have been on the market since 2003. s1 and d0 are additional classifications, and document the smoke behaviour (s) and melting behaviour under flame application (d).

Only the combination s1 and d0 is permitted for non-combustible building materials. Any higher assessment of "s" and "d" results in grading in at least European building material class B and then means e.g. flame-resistant.

The protective action against massive fire has been documented to particularly striking effect after the almost complete burn-up of a food operation in England. In the event of fire, a module that was built around the deep-frying plant was supposed to prevent the fire spreading to the building. The complete opposite happened. The building, together with the stored goods, burned down, while the sandwich cell with its rock wool core remained standing. Sandwich panels with a rock wool core are therefore being used more frequently, e.g. in the internal refurbishment of industrial buildings. A further advantage: the insurance industry also rewards the installation of non-combustible building materials in susceptible buildings with more favourable premiums.

2.Together they are strong

Non-combustible sandwich panels with an A1 rock wool core make sense in cases where traditional PUR sandwich panels can or may no longer be used. Typical examples of use occur in the following sectors:

Cold store construction with fire protection zones

Interior refurbishment of existing buildings with fire protection requirements

Walls for closely developed property boundaries (<5 m distance)

Partitions in accordance with the Shop Ordinance

Fire walls in accordance with the new Industrial Construction Directive

Requirements on building components in accordance with the premium guidelines of insurance companies

Airport buildings etc.

Sandwich panels with a rock wool core and sandwich panels with a PUR core can also be combined as required, thus ensuring a functional and visually sophisticated façade design, which does not present any thermal bridges in the area. In addition, the products are available with facings in aluminium and glass-fibre reinforced plastics for special applications in the food industry and in clean room technology. Virtually an Eldorado for planners and processors in the light construction industry!

3.Effective Characteristic of Sound Resistant.

4.Rich colors and good appearance.